Product Description

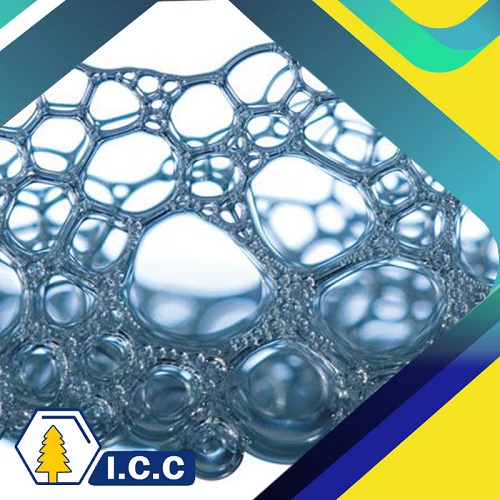

IRO-65 flotation frother is a poly glycol polymer. It is a strong frother use in a variety of applications, particularly where the ore is difficult to float and a frother blend may be required. It retains the selectivity requiring in synthetic frothers. It can be compared with” AERO65” in its applications.

IRO-65 is applied together with MIBC, MIBC-F, PINE80A frothers to increase selectivity and recovery.

IRO-65 is recommended in situations where a high degree of selectivity is required together with high recovery being a strong frother; it is recommended for a broad range of particle flotation from fine to relatively coarse particles. Although most commonly used in alkaline flotation, IRO-65 is being used in both acid and alkaline flotation system from pH 3.5 to pH 12.5. IRO-65 is water soluble and can be diluted to facilitate dosage in plants requiring a high degree of control of low frother dose. The product is stable under normal storage conditions.

If eye contact occurs, wash with plenty of clean water or amphoteric eye solution for a minimum of 15 minutes, holding the eyes open, medical advice should be followed.

If skin contact occurs, wash the affected area with plenty of water and a neutral soap for a minimum of 5 minutes.

Rinse mouth with plenty of milk or water (only if victim is conscious and alert). Get medical aid immediately.

Remove victim from exposure to fresh air immediately, if not breathing, give artificial respiration; if breathing is difficult, give medical oxygen. Get medical aid immediately

IRO-65 is regarded as practically non-toxic chemical.

IRO- 65 has a shelf time of at least three years.

IRO-65 is packed in 220 lit (net: 200 Kg) drums or bulk containers each 4 drums strapped on a pallet.

Recommended materials for storage and distribution systems of IRO-65 include: Black iron, mild and stainless steel, brass and copper. The low freezing point allows outside storage out of direct sunlight.

No comment